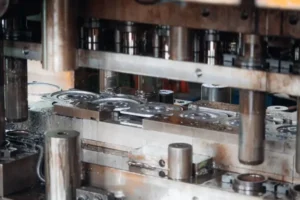

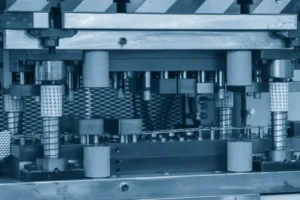

How Different Dies Improve Efficiency in Metal Stamping

As explained by Eigen Engineering in their article, “Get to Know 5 Types of Dies Used in Sheet Metal Die Stamping”, metal stamping dies play a crucial role in shaping and cutting sheet metal for industrial applications. These dies, installed… READ MORE

Understanding Metal Stamping: Process, Equipment, and Applications

As explained by U.S. Metal Crafters in their article, “Everything You Need to Know About Metal Stamping”, metal stamping—also known as metal pressing—is a cold-working process used to shape and cut metal sheets into precise components. This widely adopted technique… READ MORE

Boost Efficiency with the Right Metal Stamping Process

As discussed by IQS Directory in their article, “Metal Stamping Technologies: Types, Uses and Processes”, metal stamping has evolved from its origins in Germany during the Industrial Revolution into a cornerstone of modern manufacturing. Initially used to produce bicycle frames,… READ MORE

The Power of Metal Stamping: Machines, Methods, and Applications

As detailed by IQS Directory in their article, “Metal Stamping: Types, Capabilities and Advantages”, metal stamping is a highly efficient coldworking technique that transforms metal sheets into precise, pre-engineered components. Using specialized tooling, a punch applies force to cut or… READ MORE

How Different Metal Stamping Dies Impact Manufacturing Efficiency

As highlighted by HLC Metal Parts in their article, “4 Types Of Metal Stamping Die”, metal stamping dies play a crucial role in shaping and forming metal components. These dies come in four main types: single punch, progressive, compound, and… READ MORE

Finding the Right Press for Your Stamping Needs

As reported by SME in their article “Choosing the Right Press,” selecting the right press isn’t about which type is best—it’s about choosing the right machine for the job. Each press type—mechanical, hydraulic, and servo—has trade-offs in cost, function, and… READ MORE

How Hydraulic Press Tech Is Boosting Efficiency & Uptime

As reported by The Fabricator in their article “Hydraulic Press Technology Trends That Boost Energy Efficiency, Usability,” advancements in hydraulic press technology have steadily improved energy efficiency, automation, and usability in stamping operations. These innovations make presses more adaptable and… READ MORE

Ensuring Efficiency and Safety in Quick Die Change

As reported by The Fabricator in their article “Troubleshooting Quick Die Change in Stamping Operations,” even experienced manufacturers can face unexpected challenges when implementing Quick Die Change (QDC) systems. Addressing these issues proactively can help ensure safety, maintain efficiency, and… READ MORE

Advancements in Quick Die Change for Stamping Efficiency

As reported by The Fabricator in their article “How Quick Die Change Is Changing,” Quick Die Change (QDC) has been a game-changer in lean manufacturing, significantly reducing press setup times and downtime. While many stamping manufacturers have already implemented QDC,… READ MORE

The Power of Linear Servo in Stamping Press Retrofits

As reported by The Fabricator in their article “How Stamping Manufacturers Retrofit Presses with Linear Servo Technology,” manufacturers seeking up to 500 tons of force, especially in high-temperature applications like automotive hot stamping and aerospace titanium forming, are turning to… READ MORE