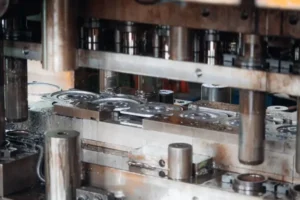

As explained by Eigen Engineering in their article, “Get to Know 5 Types of Dies Used in Sheet Metal Die Stamping”, metal stamping dies play a crucial role in shaping and cutting sheet metal for industrial applications. These dies, installed in stamping presses, enable precise manufacturing processes that enhance production efficiency and cost-effectiveness.

The five most common types of sheet metal dies include:

- Progressive Dies – Designed for multi-stage operations, these dies allow metal sheets to move through different stations, progressively shaping the final component. They are ideal for high-volume production but require precise alignment.

- Transfer Dies – Similar to progressive dies but with blanking as the first step. The metal blank is then mechanically or manually moved between stations, making it suitable for larger and more complex parts.

- Combination Dies – These dies perform both cutting and forming in a single stroke, improving production speed and cost-efficiency in stamping projects requiring simultaneous operations.

- Compound Dies – Used for multiple cutting operations in a single stroke, compound dies enable fast and high-precision manufacturing but require greater force.

- Multiple Dies – Unlike the other dies, multiple dies allow for the production of multiple components per stroke, increasing output and reducing costs in high-volume manufacturing.

Click here to learn more about Dynamic Die’s products or here to read the full article.

Article with all rights reserved, courtesy of Eigen Engineering — https://www.eigenengineering.com