As explained by U.S. Metal Crafters in their article, “Everything You Need to Know About Metal Stamping”, metal stamping—also known as metal pressing—is a cold-working process used to shape and cut metal sheets into precise components. This widely adopted technique is essential for industries that require high-volume production of identical metal parts.

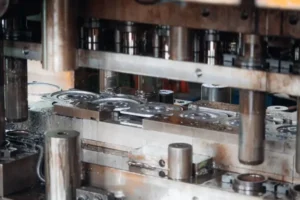

Metal stamping utilizes specialized stamping presses and dies to form workpieces into desired shapes. Mechanical presses, powered by a flywheel, are ideal for high-speed operations, while hydraulic presses offer adjustable speed and force, making them suitable for complex, low-volume projects. Meanwhile, mechanical servo presses use advanced motor systems to manufacture intricate components with enhanced efficiency.

Click here to learn more about Dynamic Die’s products or here to read the full article.

Article with all rights reserved, courtesy of U.S. Metal Crafters — https://www.us-metalcrafters.com