As discussed by IQS Directory in their article, “Metal Stamping Technologies: Types, Uses and Processes”, metal stamping has evolved from its origins in Germany during the Industrial Revolution into a cornerstone of modern manufacturing. Initially used to produce bicycle frames, the process was later adopted by the automotive industry due to its cost-effectiveness compared to forging. Today, metal stamping is essential across industries such as aerospace, electronics, and medical devices.

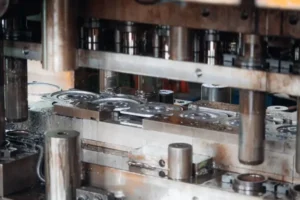

Metal stamping is a cold forming process where sheet or rolled metal, known as a blank, is shaped using high-pressure dies. While the process may seem straightforward, it involves multiple intricate steps, including trimming, embossing, coining, bending, and flanging to achieve the final product. The introduction of computer numerical control (CNC) technology has further enhanced the precision and efficiency of stamping, enabling complex designs with minimal material waste.

Click here to learn more about Dynamic Die’s products or here to read the full article.

Article with all rights reserved, courtesy of IQS Directory — https://www.iqsdirectory.com